|

|

|

TIME Precision Measuring Instrument

Leeb Hardness Tester TH170

Features:

USB communication interface

Automatic identification of impact test direction

Memory of 270 average readings in 9 files

Upper and lower limit setting

Automatically switch off

Backlight for convenient use in darkness

AAA 1.5V battery

Integrated calibration function

Technical Specification:-

| Standard Impact Device | D integrated |

| Hardness scales | HLD, HRC, HRB, HV, HB, HS |

| Measuring range / materials | See table given below |

| Measuring direction | 360° |

| Tolerance | ± 6HLD (760 ± 30HLD) |

| Memory | 270 average readings in 9 group files |

| Output | USB2.0 |

| Surface Roughness of workpiece | ≤ 1.6µm (Ra) |

| Min. radius of workpiece (convex / concave) | Rmin = 50mm (with support ring Rmin = 10mm) |

| Min. workpiece weight | 2 ~ 5Kg on stable support 0.05 ~ 2Kg with compact coupling |

| Min. workpiece thickness with coupling | 5mm |

| Min. Thickness of hardened layers | 0.8 mm |

| Indentation depth | See table in page 8 |

| Continuous working time | 150 h (without backlight) |

| Power | AAA 1.5V batteries (2pcs) |

| Operating temperature | 0 ~ 40° |

| Dimensions | 155mm × 55mm × 25mm |

| Weight | 166 g |

Measuring Range:-

| Materials | Hardness scale | Impact Device | |||||

| D/DC | D + 15 | C | G | E | DL | ||

| Steel and cast steel | HRC | 17.9-68.5 | 19.3-67.9 | 20.0-69.5 | 22.4-70.7 | 20.6-68.2 | |

| HRB | 59.6-99.6 | 47.7-99.9 | 37.0-99.9 | ||||

| HRA | 59.1-85.8 | 61.7-88.0 | |||||

| HB | 127-651 | 80-638 | 80-683 | 90-646 | 83-663 | 81-646 | |

| HV | 83-976 | 80-937 | 80-996 | 84-1042 | 80-950 | ||

| HS | 32.2-99.5 | 33.3-99.3 | 31.8-102.1 | 35.8-102.6 | 30.6-96.8 | ||

| Steel | HB | 143-650 | |||||

| CWT, ST | HRC | 20.4-67.1 | 19.8-68.2 | 20.7-68.2 | 22.6-70.2 | ||

| HV | 80-898 | 80-935 | 100-941 | 82-1009 | |||

| Stainless steel | HRB | 46.5-101.7 | |||||

| HB | 85-655 | ||||||

| HV | 85-802 | ||||||

| GC, IRON | HRC | ||||||

| HB | 93-334 | 92-326 | |||||

| HV | |||||||

| NC, IRON | HRC | ||||||

| HB | 131-387 | 127-364 | |||||

| HV | |||||||

| C, ALUM | HB | 19-164 | 23-210 | 32-168 | |||

| HRB | 23.8-84.6 | 22.7-85.0 | 23.8-85.5 | ||||

| BRASS | HB | 40-173 | |||||

| HRB | 13.5-95.3 | ||||||

| BRONZE | HB | 60-290 | |||||

| COPPER | HB | 45-315 | |||||

Standard Delivery

Main unit 1

Test block 1

Brush 1

Battery AAA 1.5V 1

Connecting cable 1

TIME certificate 1

Instruction manual 1

Warranty card 1

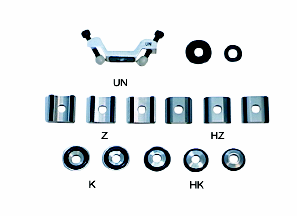

Optional Accessory

Support rings

Optional Support Rings: They are used for

tested surface whose curvature radius is less than 30mm (D, DC, D + 15, C impact

devices) or less than 50mm (G impact device)

Support Rings

| No. | Type | Sketch of non-conventional supporting ring | Remarks |

| 1. | Z10 - 15 |

|

For testing cylindrical outside surface R10 ~ R15 |

| 2. | Z14.5 - 30 |

For testing cylindrical out- side surface R14.5~R30 |

|

| 3. | Z25 - 50 | For testing cylindrical outside surface R25~R50 | |

| 4. | HZ11 -13 |

|

For testing cylindrical outside surface R25~R13 |

| 5. | HZ12.5 - 17 | For testing cylindrical in- side surface R12.5~17 | |

| 6. | HZ16.5 - 30 | For testing cylindrical in- side surface R16.5~R30 | |

| 7. | K10 - 15 |

|

For testing spherical out- side surface SR10~SR15 |

| 8. | K14.5 - 30 | For testing spherical outside surface SR14.5~SR30 | |

| 9. | HK 11 - 13 |

|

For testing spherical inside surface SR11~SR13 |

| 10. | HK 12.5 - 17 | For testing spherical inside surface SR12.5~SR17 | |

| 11. | HK 16.5 - 30 | For testing spherical inside surface SR16.5~SR30 | |

| 12. | UN |

|

For testing cylindrical outside surface, radius adjustable R10 ~ ∞ |

Download the PDF catalogue for Leeb hardness tester TH170